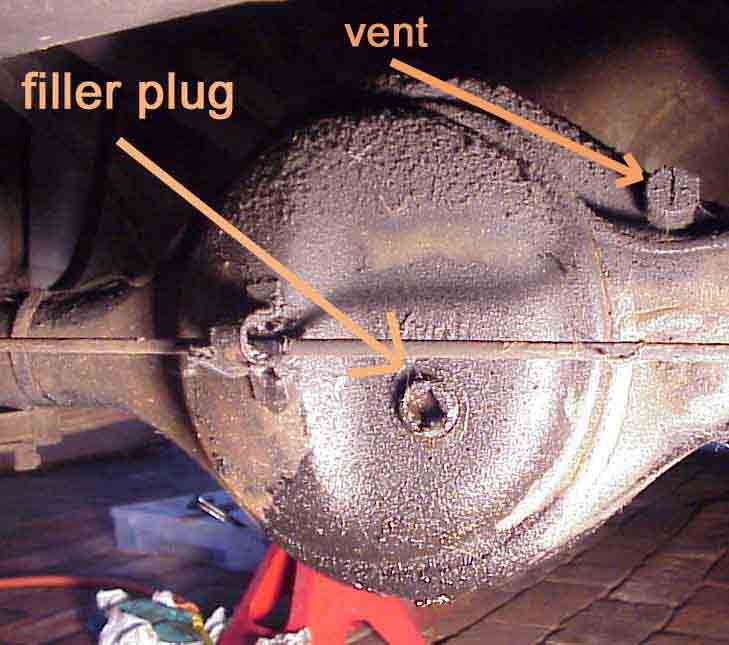

I should have steam cleaned this first, do youself a big favor and clean before you start

Remove plug at bottom and drain the oil

Mark the hub and drive line so it goes back the same way

(unless you are changing to a different pumpkin)

then remove 4 drive line bolts and pull drive line forward,

clean area, then remove 8 bolts around pumpkin

Wiggle the pumpkin and pull forward to remove

Pumpkin out

Replace torn paper gasket

Number 7386 007 (original from 1959, before upgrade to 3:90)

Rear view

After pumpkin removal,

clean insides and axle housings thoroughly

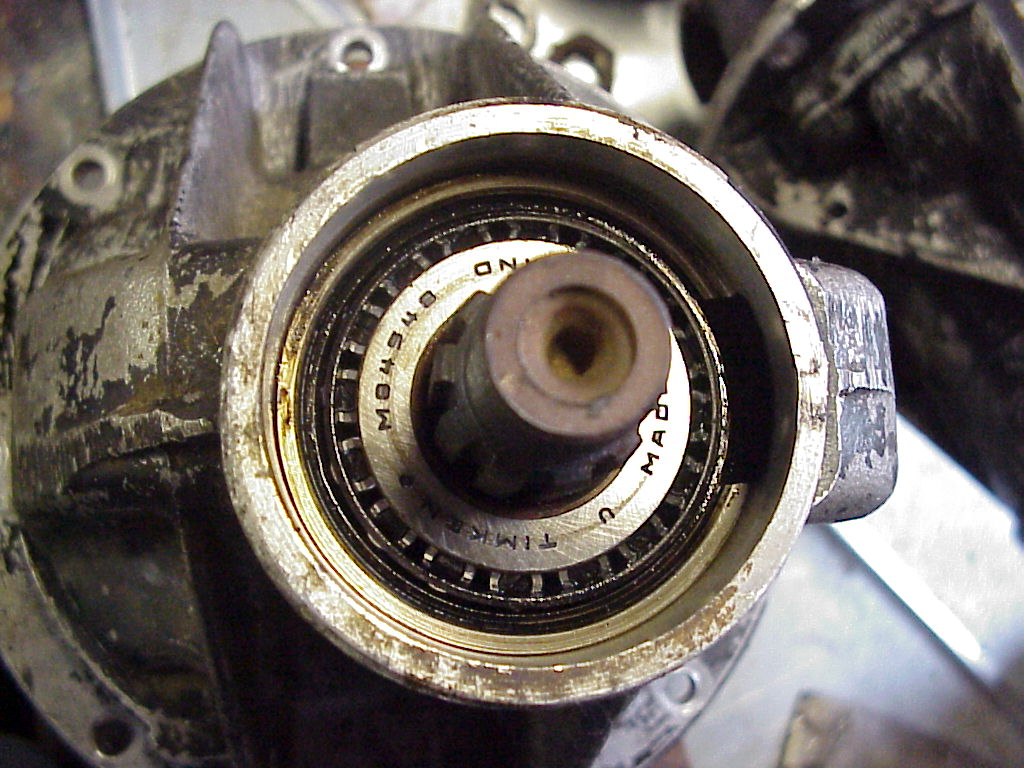

Driveline hub removed and

seal pryed up with a screwdriver

Tapered timkin bearing,

difficult to adjust the load when

re-installing the driveline hub !!!

10 and number 39 (39 teeth on large gear)

I should not have taken the driveline hub off since getting

the correct load back on the bearing is very difficult.

If it does not leak or grind, leave it alone

To keep the right preload on the pinion bearing and hub

when removing and replacing the pinion seal, mark

the position of the nut on the pinion with a center punch

(just put a little dot on the nut and one right next to it

on the pinion shaft). When you retighten the nut,

just line it up with the dot on the shaft.

You could also use a sharpie pen, but be careful

not to erase the mark if you are cleaning it up!

Remove plug at bottom and drain the oil |

Mark the hub and drive line so it goes back the same way |

Wiggle the pumpkin and pull forward to remove |

Pumpkin out |

Replace torn paper gasket |

Number 7386 007 (original from 1959, before upgrade to 3:90) |

Rear view |

After pumpkin removal, |

Driveline hub removed and |

Tapered timkin bearing, |

10 and number 39 (39 teeth on large gear) |

I should not have taken the driveline hub off since getting |